High steel parts machined resistance and controlled.

Suitable for all types of hard and abrasive ores.

(granite, quartz,…)

Adjustment, clamping and unclamping from a central location.

Easy head and bowl extraction.

Setting from 50 to 460 mm.

Power motor from 30 to 400 Kw

Roc Impact cone crushers, used across the world in many mines and quarries

are renowned for being reliable and robust.

Two main types of cone crushers are available to you:

Both types are intended for secondary or tertiary crushing whether in a fixed or mobile installation for highly abrasive materials.

Its simple design and sturdy construction make the RC Cone crusher ideal for any crushing operation.

The upper and lower parts of the crusher frame with RC cone are securely assembled with hydraulic device.

Each part is made of high-strength steel, which allows the frame to withstand high stresses during the crushing operation.

In addition, guards helps limit wear when materials pass through

Continuous adjustment using a crown driven by a hydraulic motor which facilitates

maintenance operations.

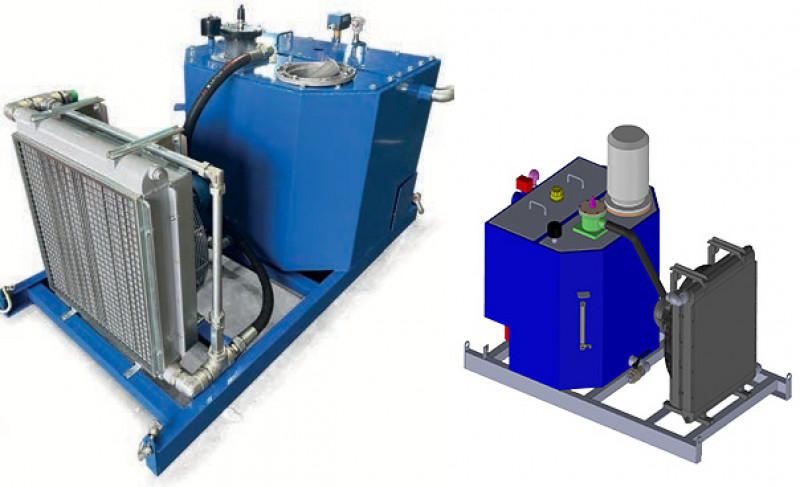

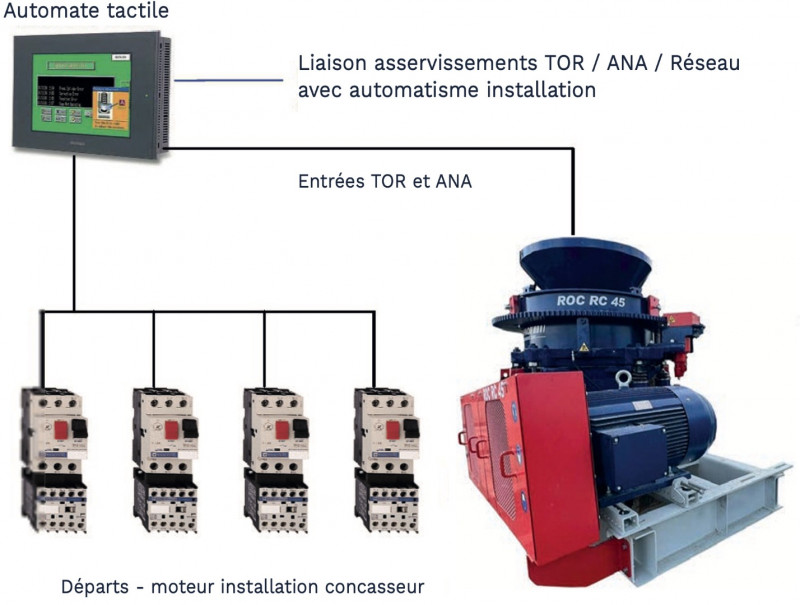

RC Cone crushers are equipped with hydraulic cylinders for clamping and unclamping.

The device is controlled using a hydraulic power unit.

| Type | Capacity (T/h) | Power (Kw) | Weight (Kg) |

|---|---|---|---|

| RC 36 STD / SH | 40 - 135 | 90 | 5500 |

| RC 45 STD / SH | 85-245 | 132 | 11800 |

| RC 54 STD / SH | 110-445 | 250 | 16800 |

| RC 66 STD / SH | 135-625 | 315 | 24000 |

| RC84 STD / SH | 170-780 | 355 | 35000 |